As you may recall from earlier posts, we accepted delivery of our Airstream travel trailer back in August of 2019. Since then we have put over thirty-thousand miles on our coach and over forty-one thousand miles on our tow vehicle.

During that time we have given very little thought to our tires other than inspecting them before and during trips, keeping the air pressure at the suggested level for both vehicles, and covering the camper tires when in the same place for more than a few days. We also use a tire protectant spray every two thousand miles. So I guess we do give more than a little thought to our tires.

Last week, when preparing to move from an RV Park to our own land, I noticed one of the tires was looking low. I had just checked the pressure a few days ago before we arrived at the RV Park, so this was troubling. Very troubling as the usually 80 PSI tire was down to 65 PSI.

Upon closer inspection I found a small screw embedded into the tread of the tire.

Luckily I have experience with small punctures such as this, and the screw was in a location that was easily repairable without removing the tire from the Airstream. This picture also tells me that the tire is wearing a little unevenly and, as we will see in other photos, it’s time to order a fresh set of tires for our coach. Back to the repair…

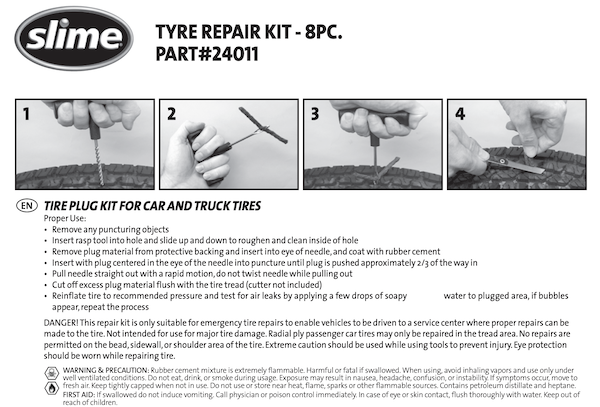

The tools required to plug this kind of puncture include:

- A screwdriver to remove the offending screw (a pair of pliers would also work)

- A plug kit (I use the Slime branded kit)

- A razor knife to trip the plug flush to the tire

- A compressor to inflate the tire

Step One: Remove the offending object.

Step Two: Clean out the puncture hole using the abrasion tool provided in the kit.

Step Three: Thread a plug through the needle tool provided in the kit and coat with rubber cement.

Step Four: Plug the tire and quickly pull the tool back through the hole.

Step Five: Inflate the tire and check for leaks.

Step Six: Trim the Plug flush to the tire.

We will be monitoring the tire pressure for a few days to ensure that the plug is holding air.

Instructions from Slime.

Tire plugs aren’t hard, but there are some disadvantages to running on a plugged tire. Most tire manufacturers don’t recommend taking a plugged tire to the maximum speed or temperature rating of the pre-plugged tire. Plugs should only be used to repair a tire when the puncture is within the tread and less than ¼” in size. Also note, that patching a tire yourself may void the warranty.

One should never attempt to plug or patch the sidewall of a tire.

Given that we have over 31,000 miles on these tires and they are showing uneven wear on the inner tread as well as dry rot on the sidewalls near the start of the tread, it’s time for new tires. We’ll be upgrading to Carlisle trailer tires on all four wheels.